EVOLUTION OF THE SWITCHBOARD ENCLOSURE

16 Sep 2024

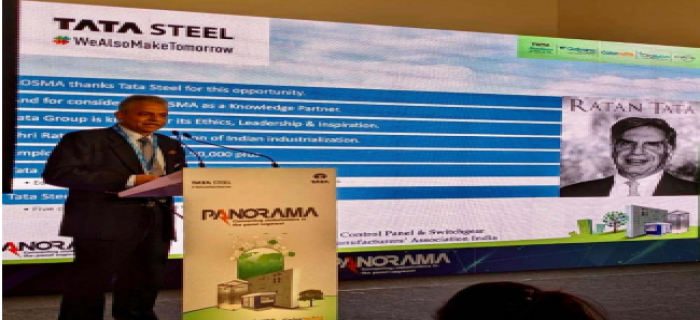

On the 2nd of February 2023 at the Taj Connemara Hotel, Chennai, Tata Steel invited Panel Builders, Elevator Manufacturers & DG set assemblers amongst their key accounts for a Panorama Seminar connecting stakeholders in the panel segment. On behalf of COSMA (Control Panel & Switchgear Manufacturers’ Association), I made a Presentation on the “Evolution of the Switchboard Enclosure.” It was a very gratifying experience.

The living legend of this Tata empire is Mr Ratan Tata, who embodies ethical conduct, dynamic leadership & fascinating results for this organisation. The Tata Group and its subsidiaries employ more than 7,50,000 people, almost as much as the population of urban Chennai! Tata Steel, with its subsidiaries, associates, and joint ventures, is spread across five continents with an employee base of over 65,000 and a consolidated turnover of Rs 1.5 lac crores.

In COSMA, founded in 1988, we have close to 500 members and the numbers are fast growing on an all-India basis. The theme is to Unite Panel Builders so that the collective influence can do good for the Electrical Distribution Industry in India and the world at large. COSMA is also a sub-division in IEEMA, representing the Switchboard Industry.

A Quality Division has been set up in COSMA to establish standards in Panel Building for COSMA members, such that they are trusted more by Specifiers and End Users when Panel Boards are required for projects. Members are also exposed to the Best Practices in Industry & compliance with the latest International Standards like IEC 61439-1&2 for LV Switchboards, IEC 62271- 200 for MV Switchboards and so on.

An Export committee is also formed in COSMA to encourage Members to export their product solutions overseas, firmly establishing the AtmaNirbhar Bharath Vision. Software, Artificial Intelligence and Industry 4.0 are all instituted into the fabric of futuristic thinking in the members of COSMA, through appropriate factory visits, exhibition participation and collective learning opportunities.

COSMA works closely with Tata Steel to acquaint their members and industry at large with the variety of steel solutions available, gets educated on the latest innovations in the metallurgy of metals and their availability and leverages the best of these for the cause of making electrical distribution safer, better & greener. COSMA has signed an MOU with Tata NEXARC a digital growth platform that enables emerging businesses to grow, solve challenges & optimise processes in a B2B space.

As a knowledge partner of Tata Steel, on behalf of COSMA, I commenced my talk with the amazing fact that the Indian Panel Building Industry today is approximately Rs 18,000 Crores including the Large & MSME sectors of which:

• Process automation would be Rs 7000 Crores with a growth rate of 8% approx.

• Factory automation would be Rs 2000 Crores with a growth rate of 15 to 18% approx. &

• Electrical distribution would be Rs 9000 Crores with a growth rate of 15 to 18% approx.

Now, tracing the steps back to just 5 to 6 decades ago, Switchboards then were made in Cast Iron! Slowly, it transitioned to CRCA Sheet Steel with spray painting technology. Angle Iron was also used to form the structure of the Panel Board with sheet steel cladding around in welded fashion. Subsequently, the era of profile-based enclosures commenced in welded, semi-modular and truly modular designs.

Unlike welded enclosures, the modular ones had a number of significant features, advantages & benefits. The concept of standardisation, systematisation and simplification stepped into this industry significantly. They were adaptable to multiple makes of switchgear, flexible with possibilities of hinged doors reversibility and merging & de-merging of modules in a vertical and with a host of other versatile capabilities.

The concept of defining the height, width & depth dimensions in steps of fast-moving ranges, enhanced availability, speed in construction and even affordability, thanks to economies of scale. This also empowered software to arrive at the mechanical bill of materials in such mechanised solutions, which facilitated not only quick quotes but also accuracy and with catalogue numbers. Barcoding supported the easy identification of parts from the inventory, reducing lead times in assembly.

Even the International Standards that govern these switchboard enclosures, evolved from IEC 60439 to IEC 61439 which included the Switchgear manufacturer in the circle of responsibility. Certifying bodies from UK, Europe & US like Intertek ASTA, Dekra & UL consequently entered India to establish their accreditation services in these areas too.

The modular technologies allowed the imagination of man to fructify fascinatingly. The industry saw the advent of cage nuts, riveting technologies, clinch nuts and so on. Different kinds of metals too were introduced apart from HR & CR Sheet steel. Galvanised Iron in sprangle free, skin pass and in micron coatings of 125 & 275 gsm was introduced. Pre-coated sheets up to 1mm in thickness entered the markets. These were available either plain or with a plastic sheet covering to avoid scratches during manufacturing.

Where India needs to catch up with the world is in the availability of 2mm thickness & above of Alu Zinc sheets. This is an alloy of Aluminium and Zinc that outperforms the powder-coated CRCA Sheet Steel by 22% in its anti-corrosive property. The latest invention in metallurgy is the introduction of Magnelis by Arcelor Mittal, albeit in their overseas plants only and this is termed ZAM amongst Chinese manufacturers. This is a combination of Magnesium, Aluminium and Zinc, making the metal stronger and more economical as well, as Magnesium partly replaces the more expensive Aluminium.

Tata Steel confirmed that AluZinc in thicknesses of 2mm and above would be introduced in 2025 and ZAM thereafter in their Indian plants. They took notice of the fact that Switchboard Enclosure manufacturers overseas like Tekpan & Emiter to name a couple, were already using Magnelis material for their enclosures, giving them a unique selling proposition.

The quick growth in inventiveness & innovation in the panel enclosures happened, not just on account of significant manufacturers like Rittal, Hoffman, Logstrup, Cubic, Elsteel & Modutec entering the organised segment here, but also switchgear companies like Schneider Electric, ABB, Siemens, L&T and the like introducing their own design and brand of world-class switchboard enclosure solutions. All these companies further brought in the concept of Panel Partners wherein for a License Fee, they transferred technology in enclosure manufacturing, which enhanced not just the learning of better methods here, but also their enclosure/switchgear sales.

The trend in IEC 61439-1&2 for LV Switchboards and IEC 62271- 200 for MV Switchboards also saw a steep upward trend since the last decade in India and several parts of the world. The qualification of such standards brought along with it the much-needed trust in this safety solution. The Specifiers started making these standards mandatory in most of their premium projects and the End Users too saw value in the culture of compliance which enhanced reliability.

Further Type Tests like IEC / TR 61641 for Internal Arc and IEC 60068-3-3 for Seismic withstand capability too brought in a higher level of criteria that needed to be met for applications that were seen to need these. The focus on corrosion resistance, mechanical impact, and IP (Ingress Protection) Tests thus got further reinforced, making a Declaration of Conformity by the Panel Builder a requirement, especially in Data Centre, Oil & Gas and Power Projects.

Simultaneously, pioneering progressed in the switchboard enclosure accessories too. Conventional metal locks saw alternatives with polyamide ones. Plain lock lips saw competition from compression-type technologies. The opening & locking of the 3-point locking systems saw the digital number locks, biometric ones as well as remote sensing inventions.

Rubber gaskets started coming in different avatars of better chemical and heat-resistant varieties. To make the dust and water protection seamless and in different heights and widths as required, the polyurethane foam gasket dispensed by CNC machines took the market by storm.

Tripods in Alu-Zn alloys in different sizes and dimensions got made from gravity to pressure die cast and even in iron & were used in the eight corners of the enclosure verticals. The hinges used were totally metamorphized from the male-female cylindrical hinges that would get welded to the frame and the hinged door to wellengineered bolted types in formed sheet metal to even springloaded ones. When volumes increased, these hinges were made in polyamide, aluminium extruded ones to alloys of aluminium and zinc in die-cast varieties.

Today, India seeks to become the China +1 destination for manufacturing for the world. For this to happen domestic steel production has to go up several times. The staggering statistic is that China alone caters to 55% of the world’s steel production! And then as stated above, India is yet to produce certain grades of alloy metals like AluZn and ZAM. Tata shared the news of their rapid expansion in manufacturing capacity across more than 1 location in the Country. Other steel manufacturing companies too are under conscious & aggressive expansion like JSW.

Given the increasing strength of the Dollar against the Rupee, exports too, need to be given a huge thrust. High growth Countries like MEA, GCC, SEA & ANZ need to be targeted to make this happen. COSMA is working closely with IEEMA (Indian Electrical & Electrical Manufacturers’ Association) to make this happen particularly for the MSMEs.

leave your comment